Home>>News

Machineryshops.com

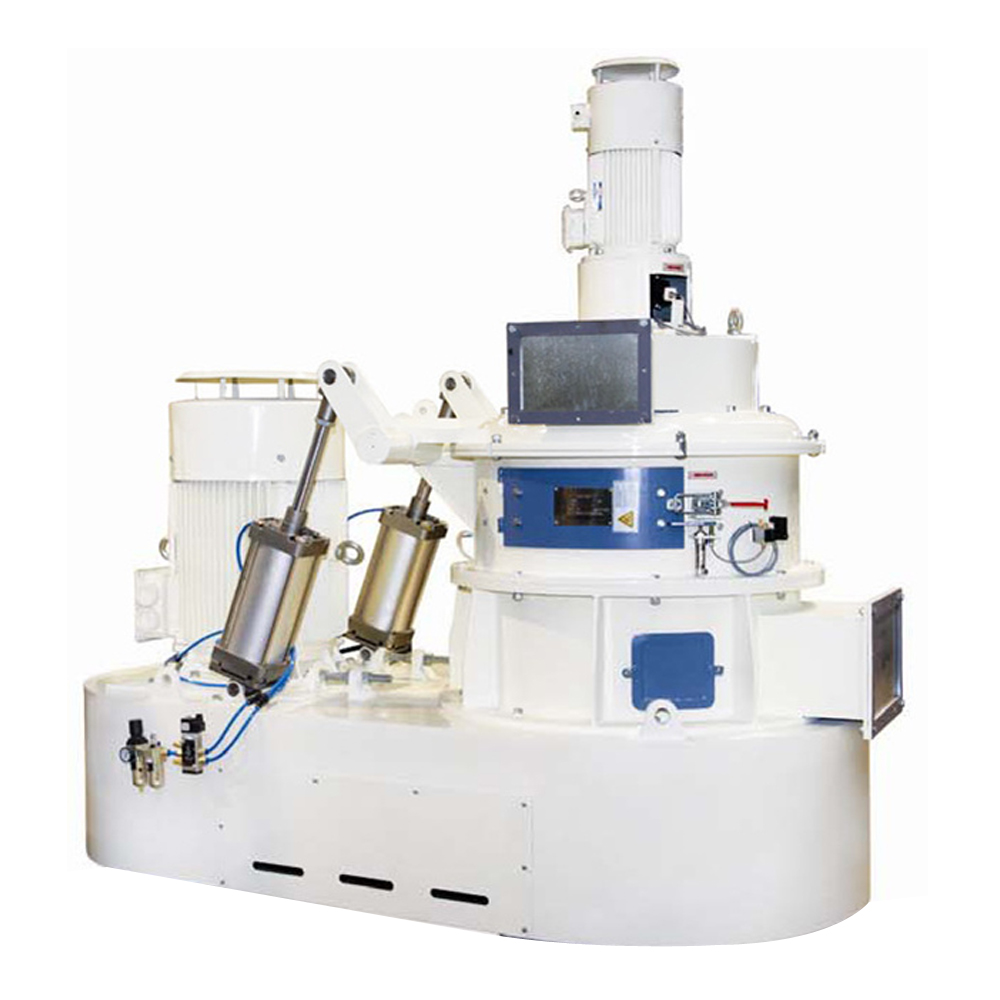

How to Choose Suitable Grinder Mill

There are too many types on feed machines but you should know how to pick up a best grinder mill, then following is some principles available to choose.

First, you should consider what raw materials could be crushed with the grinder machine. If you crush cereal-based feed, the hammer mill is optional, while crush wheat bran feed, the jaw crusher is available; if you want common machine which can crush grain, valley of bread and straw, tangential feed hammer mill would be the best; if you need to crush some mineral feed, such as shell, you can choose shells screen mill; if the pre-mixed process is required, and the product granularity can be carried out, you should pick up no-sieve crusher mill.

Second, you also should consider the production capacity on the feed mill, real-time production. It should be noted that: (1) the hourly output on the instruction book and nameplate is subjected to grinding corn with safe storage moisture content of water (about 13%) and φ1.2mm aperture sieve. Because corn is commonly used in feed grain and diameter 1.2mm aperture sieve is a common minimum sieve, which takes the best production into account. (2) The production capacity should be slightly larger than the actual needs of the production capacity to avoid hammer wear and duct leakage.

Third, the energy consumption of the mill is so large, so at the time of purchase, you need to consider energy conservation.

Four, you should consider discharging way. There are three ways by the mean: weight blanking, vacuum suction and mechanical transport. Small machines usually adopt weight blanking to simplify the structure of the material. Most medium sized grinders are with vacuum suction means, and the advantage is to suck out of the water and reduce the product humidity to improve the grinding efficiency of 10-15%, reducing the dust of grinding chamber.

Five, dust and noise. In feed processing, dust and noise are mainly from the mill. When you purchase the machine, you should fully consider for this two sanitation targets. If you had to choose a high-grinder with noise and dust, you should control dust to improve the working environment which is conducive to the health of the operator.

Reviews

Write a review

If you would like to write a review, please login first.