- Overview

- Customer Review

- Purchasing guide

- Service

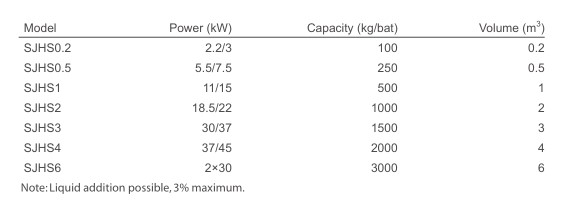

- Specifications

SJHS Series Double-Circle Paddle Mixer

--High efficiency,High homogeneity,No residues

Detected by the state authorities:

FAMSUN double-circle paddle mixer

has mixing homogeneity of97.7%(i.e. CV value =2.3%),

natural residue percentage of0.1%,

and unit power consumption of0.30kW*h/t.

FAMSUN Double-circle Paddle Mixer is independently researched and designed by FAMSUN and wins international patent technologies. It has advantages of quick mixing time,high homogeneity and no residues.

■ High homogeneity

International patent double-circlerotor design, inside and outside double-circle paddle design, reinforcing convection, shearing, and mixing effects.Mixing homogeneity is up to 97.7%.

■ No residues

Adjustable gap between paddle and casing, ensuring extremely low residue ratio, avoiding materials cross contamination; fully open discharging gate, mixed materials are discharged completely in no time, no residue.

■ Zero leakage

Discharging gate is sealed with rubber air bag,realizing zero leakage;at the shaft ends, the packing seal is specially designed to ensure zero leakage.

■ Human friendly

The 14px access door in reasonable design, ease of cleaning and time saving; elevating type liquid addition device "air atomization" contributes to high-precise addition,which ensures homogenous mixing without generating any agglomeration.

Step instruction:

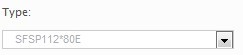

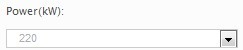

1、Click "type" and "power" to choose the type and power of commodity you need.

2、 Click "add to cart"to adding commodity to cart. If the commodity you are purchasing has no accurate price, please click "add to inquiry basket" and fill in your personal information. Our staff will provide quotation for you when verify the orders and automatically help you to complete the purchasing list.

3、You can choose needed logistics way and delivery place when purchasing.

4、 Our staff will provide quotation according to your chosen logistics as verifying the orders. You can click "to pay" to check price and payment. If you have any question about quotation, please contact our staff in time for answers.

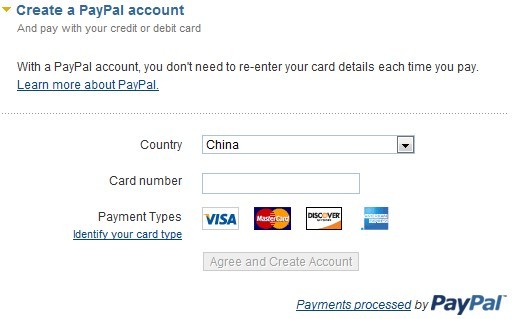

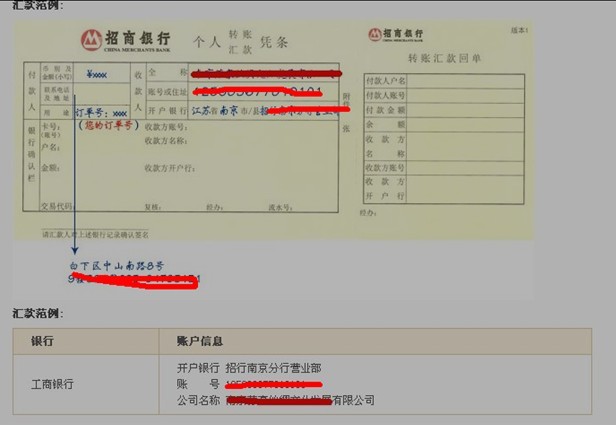

Payment methods:

We support online PAYPAL payment and offline TT payment. Please inform our staff after finishing the payment.

Quality description:

All of our machinery are tested strictly when shipped from factory. And we apply machine one-year warranty.

Contract description:

Generally, we default the online order as the contract. If you need a formal contract, please contact us, we will provide you with the formal contact.

Delivery:

1,Once the advance payment is received,we will arrange production The percentage of advance paymen must be 30% of total amount.

2, Delivery time for single machine is at least 45 days and usually about 2 months. For the complete equipment, we will make proposal, design drawings and confirm with you, thedelivery cycle about 3 months.

3, Total amount must be paid prior to the delivery. TT and online payment are accepted.

4, If you are not satisfied with the offer of logistics, you can appoint logistics company.

5, One-time delivery and partial delivery both are allowed.

6,For machines, sea transportation is recommended; for accessories and parts, air transportation is optional.

7,All price information on website is for reference only, final quotation will be determined by our sales staff according to customers sutitation after inquiries and orders received.

Note:Under special circumstances, the date of delivery will be extended for a reasonable length of time.

Country of origin:

Products are manufactured by Jiangsu Muyang Group Co.,Ltd. of China. Adopting international advanced technology, Muyang imports large proportion of components to do the final assembly.

Acceptance of the goods:

A check on appearance should be made immediately when the equipment is transported to the destination. If it is sure there is any damage caused during transport, a necessary claim procedure must be taken according to the supply contract. The repair expense shall be borne by relevant risk undertaker.

Maintenance and cleaning

Only professional persons can carry out maintenance and shall well know relevant stipulations in the documents provided by us. These stipulations are helpful for keeping the equipment in good condition, reducing wear and prolonging the service life. Cleaning shall be done according to relevant legal stipulations and explanations in the documents provided by us.

Storage

The equipment, which cannot be installed in predetermined place immediately, must be stored in a weatherproof place with facilities against external infringement in original packages. Any loss arising from storage shall be only conducted as per the principle specified in the Supply Contract.

Installation

The equipment and parts manufactured by Jiangsu Muyang Group shall be installed only by the trained technical personnel based on installation specifications provided together with the equipment.

Startup and commissioning

Startup and commissioning shall only be done by trained personnel. The instructions and operation regulations in provided documents before startup. Lubricating before startup, such as oil for variable speed devices.

Accident prevention

The accident prevention rules in related documents must be well known and MUYANG Group devotes to manufacturing machinery equipment according to Standards (CE Certification Standards).

Customers shall tell us the local manufacturing. Additional expenses there from shall be borne by customers.

contact us

If you have any questions or after-sale problems, please contact us in time.

TEL:+86-02134970680(00:00--10:00 GMT)

E-Mail:

Notes:each batch mixing amount is caculated by volume density 0.5t/m3;SJHS8 driven by double motors.