- Overview

- Customer Review

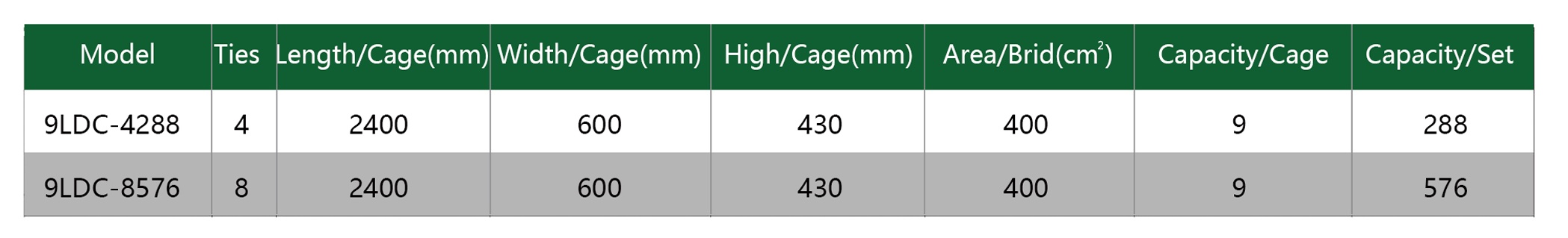

“H”Type Layer Cage System

HuaLi Co.,Ltd professionally tailors solutions for“H”type layer cage system, including auto-feeding system,auto-drinking system and auto-manure removal system,ventilation and control system.

Features

Advantages

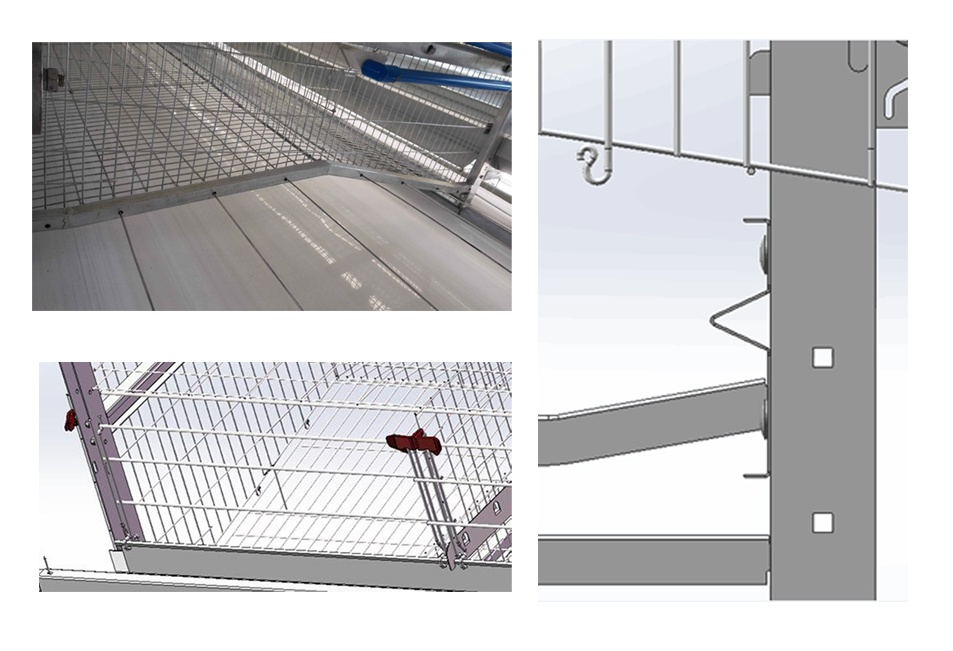

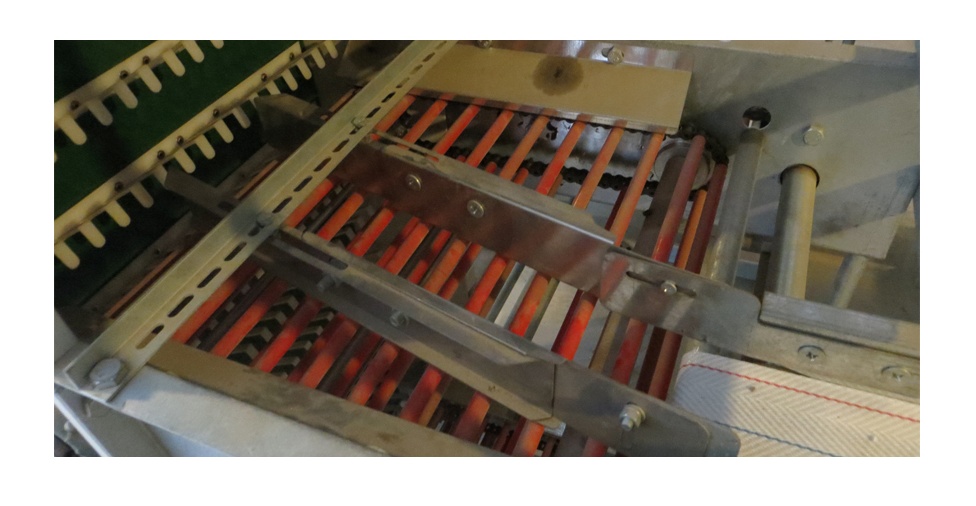

Reasonable design of bottom screen, lower egg breaking rate.

The feed trolley has a feed balancing device to ensure uniform feeding.

Reasonable cage height design between two tiers leading to good ventilation ,lighting and preventing from disease infection

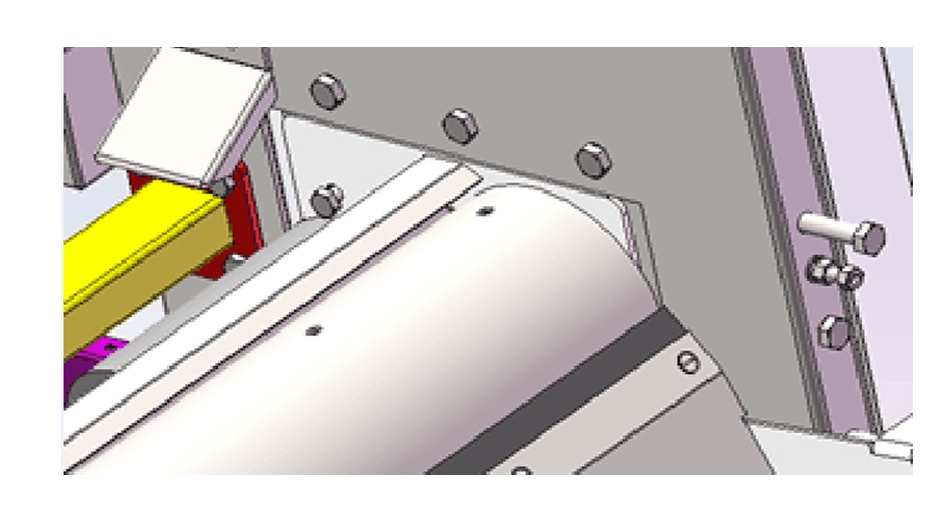

Egg collector and conveying belt with guiding device to effectively reduce the egg breaking rate.

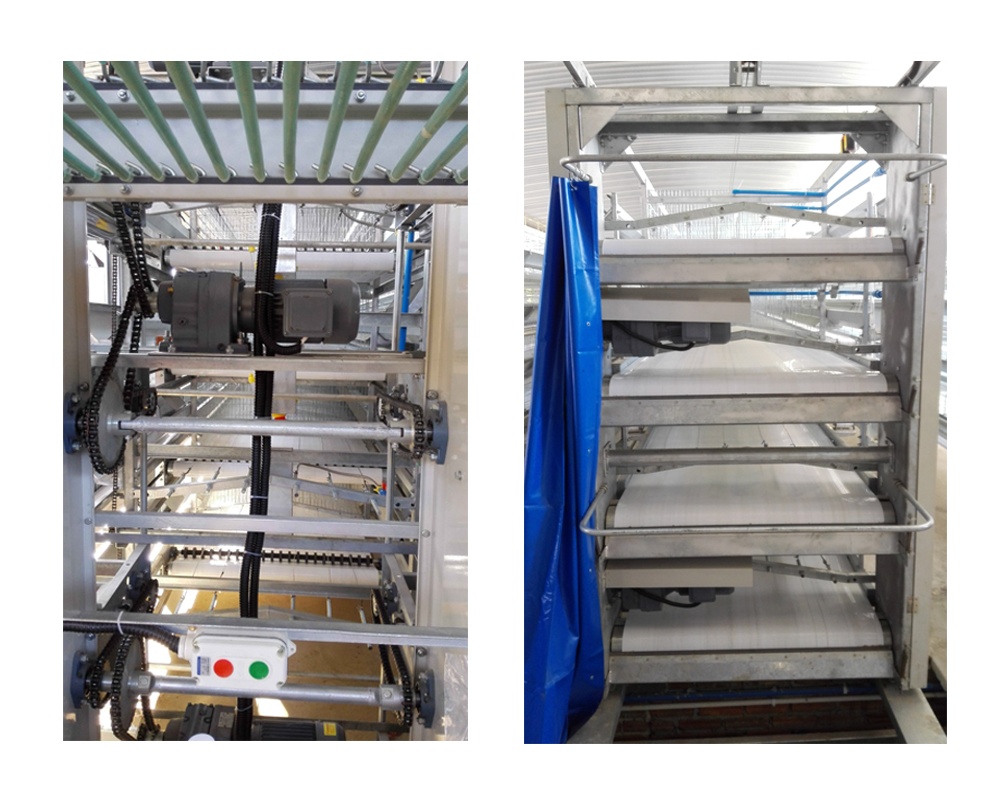

Manure belt with disalignment device.

Double scraping manure unit.

The key components are of international well-know brands leading to stably runing.

Advanced automatic operation system ,saving labor cost .Unmanned management of environmental control system leading to safety and stabilty.

Advantage Description

|

Reasonable design of bottom screen, lower egg breaking rate. With space between the bottom net and the side plate to make the whole bottom net at an angel for ensure the egg roll off to the egg conveyor belt. With reasonable space of support steel wire for bottom net,increasing the flexibility of the bottom net and being durable. |

|

Egg collector and conveying belt with guiding device to effectively reduce the egg breaking rate. |

|

Manure belt with disalignment device, effectively prevent from manure belt off tracking and increase the service life. Manure belt remove system ensure the house clean and sanitary,providing a good and comfortable environment for chicken. |

|

The feed trolley has a feeding balancing device to ensure uniform feeding. Increase the brush for feed trolley, clean and sanitary. |

|

|

|

The key components are of international well-know brands leading to stably runing. Manure belt import from Italy with high quality and stable runing. Motor for feed trolley and manure belt and bearing all adopt international well-know brand in order to guarantee long-time service life. |

600,000 Layers Project