Home>>News

Machineryshops.com

How the Pelletising of Livestock Feeds Can Save You Money

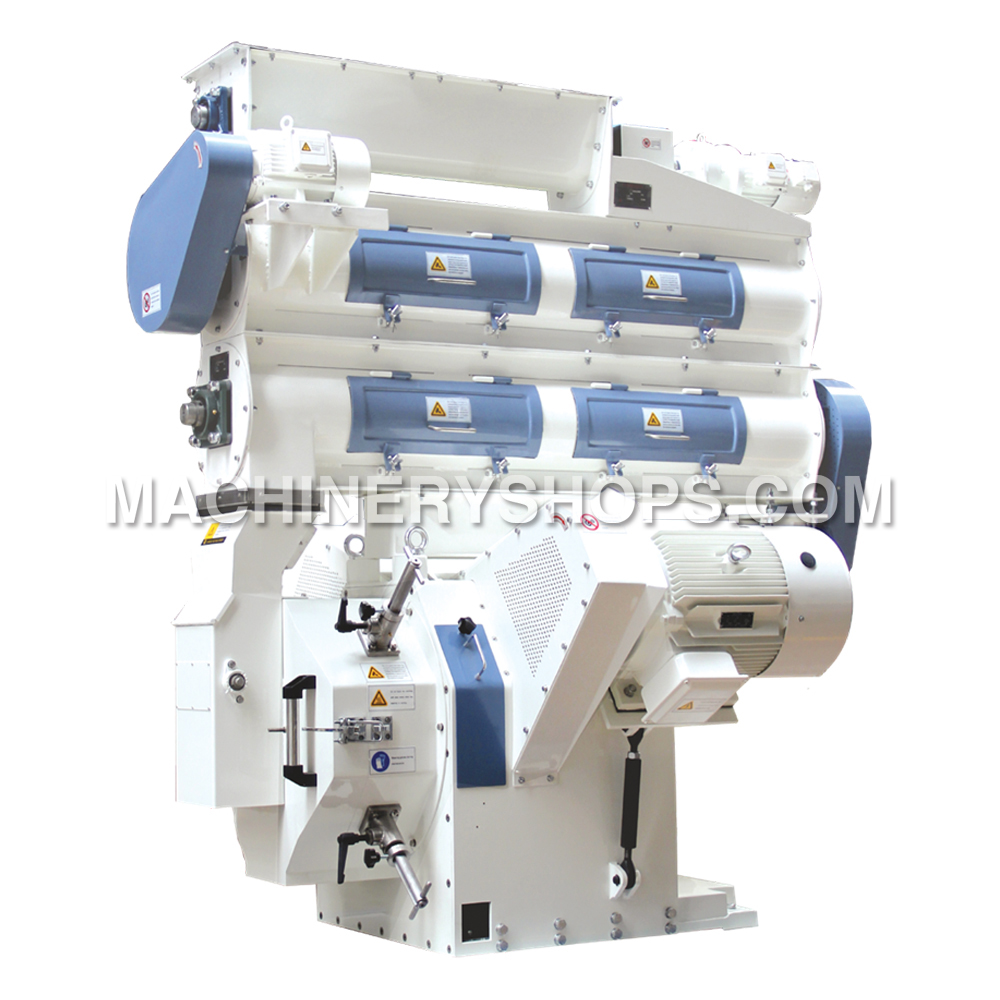

Muyang believes in supplying full pelleting solutions, in other words, all the equipment required from milling the material up to the final product.

Feed is the greatest cost factor in animal production. Even in the case of sheep farming where more roughage is fed, feed costs can still make up to 55% of the total sheep production cost. For poultry the corresponding feed costs figure will be about 70% of total chicken production costs.

The main market for Muyang's pelleting machines is the animal feed market. Pelleting of animal feeds is becoming a widely popular and a modern method of saving money and adding value on farms.

The savings is not only based on the fact that the middleman is eliminated, but also because the farmer has control over his formulations. In this way the farmer can add value to poorer quality feeds and thereby reducing cost without compromising overall quality. In addition to these benefits, the farmer saves up to 30% of his feed cost, which would normally be wasted due to selective- and wasteful eating patterns of animals.

As discussed below, there are also other improvements in the feed's absorption properties when it is pelletized.

The benefits of pelletising:

***Improved animal performance. Higher energy intake levels occur while animals spend less energy to graze.

***Pelleted feed promotes animal growth due to better feed conversion rates, in other words better utilization of the nutrient value of the feed.

***Due to the heat generated in the pelleting process, it improves the uptake of protein in the rumen of ruminants (thus a higher bypass protein), thereby increases amino acid availability and increases animal performance

***Pelleting reduces wastage with up to 30% versus loose feeds, due to poor and selective eating habits

***Pelleting will eliminate dust that will increase the palatability or taste of the feed

***No wind loss occurs on pellets

***Better mixing of raw materials takes place; therefore no selective feeding will take place.

***The ration is less bulky and therefore reduces storage space requirements and allows for easier transportation and handling

Typical feed wastage calculations for a medium-sized farm:

***At a medium-sized farming operation the wastage of loose feeds can be up to 200kg per day and even more, depending on feed volumes

***With a ration cost of R2,500 per ton, wastage of R500 per ton therefore occurs

***Over a period of 365 days, wastage will cost the farmer as much as R182,500

***With a feed conversion rate of 6:1, a loss in weight gain of ± 12,166 kg will occur with loose feeds versus pelleted feeds

***At a feedlot price of R21 per kg, approximately R255,486 is lost per year

***The total loss calculation can be as much as R437,986 per year

Potential value adds through pelleting:

***Suppose the average price of Lucerne is R 1,400 per ton

***It costs R80 to mill the Lucerne and R100 to do pelleting, therefore R180 + R1400 = R1,580 per ton

***Suppose the average price for commercial Lucerne pellets is R2,400 per ton

***The profit or value add is therefore R820 per ton

Machineryshops.com provide different types of feed machiney, and you can pick up them according to your real needs.

Reviews

Write a review

If you would like to write a review, please login first.