Home>>News

Machineryshops.com

Product Update Smooth Pelleting for Stable Production and Quality

Physically or chemically, feed processing techniques would alter molecular structure of nutrients in feed ingredients. These changes can have significant effects on nutrient utilization by animals, which may consequently improve production performance.Like other industries, feed processing technology continues to evolve as we continually see some significant advances in processing equipment and techniques. Currently, there are multiple processing techniques available for manufacturing feeds for birds, pigs, cattle, fish, shrimp, etc. However, feed suppliers' expectations are not just machines and technologies that produce feed, but those produce products hit precise quality targets in terms of size, density, nutrition, digestibility and economic.

The benefits of processing techniques are dependent on animal species. Animals may not respond in the same way to a specific type of processing technique. Therefore, to research the performance of animals fed by feed produced from different techniques, to find the exact feed solution for the specific specie, and to innovate the technology to further its economical benefits are critical for the feed and animal husbandry industries.

With this concept in mind, Muyang researchers have remained exclusive focuses on innovating and developing specified feed machinery and processing solutions for the specific animal species over past decades.

For poultry feed and swine feed manufacturing, our in-depth feed manufacturing knowledge and years’ experience of working with our clients and their customers tell us that pelleting is the best answer. It is cost-efficient and feed pellets are of excellent feeding performance. For instance, poultry diet fed as intact pellets had approximately 30% more calories of productive energy than mash; pigs fed pellet diets vs. mash have 3-6% better feed efficiency.

That's why we continue to innovate and roll out the V series pellet mills for poultry and swine feed productions. We believe that small enhancements on machine performance and pellet quality are added value to feed manufactures and farmers.

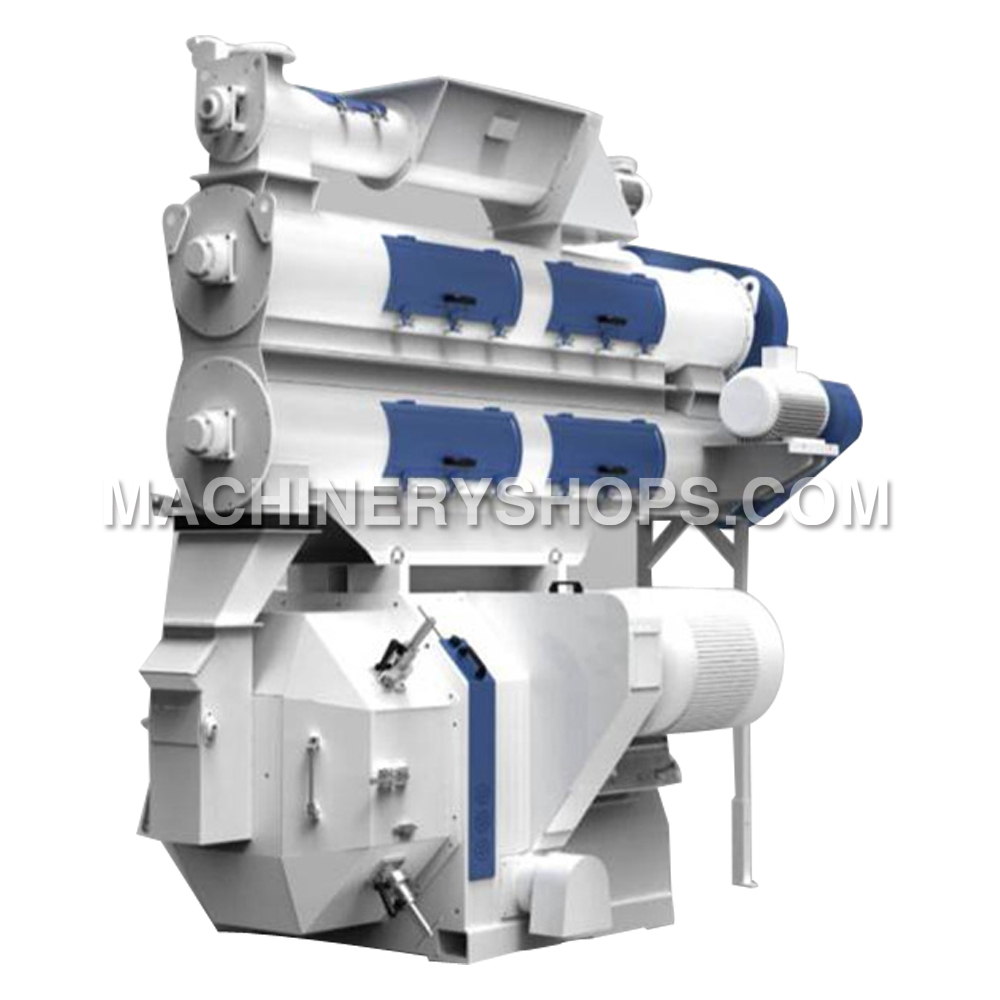

There are two models of the V series pellet mills. The V6 is the powerful model with power of 150kW and 550mm die diameter, delivering high pelleting performance of up to 18t/h for pelleting poultry feed with 3.0mm die holes. The smaller version V4 comes with motor power of 110kW and a 460mm die, suitable for production capacities from 8t/h to 14t/h. Both of these models fit the exact expectations of feed suppliers on poultry and swine feed manufacturing because of their distinguish stability in production performance and feed pellet quality.

The V series pellet mills secure noticeable pelleting stability by unique driving system, novel ring die mounting structure, reliable suppor and wearing reduction design.

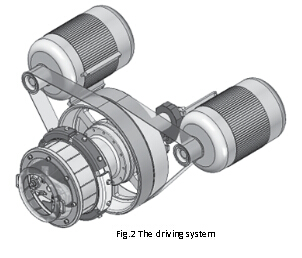

***Unique driving system. The new driving system is a major contributor to pelleting stability. Thanks to the double timing belts driving system, load on rotor can be evenly distributed onto the two main motors synchronously, and the motors output same torques simultaneously as well. Again, because of the synchronization feature, timing belts are not so sensitive to the difference of load, bringing improved anti-blockage ability to the pellet mill.

Guard hoods with optimized profile on both sides and the machine body form a cooling chamber, in where fresh air is led to cool the driving system consistently in desired track and to keep the timing belts running at a reasonable low temperature. This design ensures stable driving and reduced transmission loss, moreover, light vibrations and low noise.

***Novel ring die mounting structure. As shown in Fig.2, the ring die is held and fixed onto the pellet mill rotor with eight hoop clampers. Through firmly connection, ring die rotates together with the rotor stably without any vibrations. On the other hand, the sectional hoop clampers are easily accessible, while their clever design significantly reduced the time needed for die chang.

***Reliable support. Except that the machine body is mounted on a solid cast metal base, the bearings of main shaft can be lubricated automatically and kept in good lubricating conditions all the times because of the auto lubricating system, which contribute to a long time reliable running. More than that, the supporting area for main shaft is increased to further stabilize running performance.

***Wearing reduction design. Innovations on wearing parts and countermeasures to prevent vibration during running are other major factors to guarantee the pelleting stability. Made of increased wearing resistance material and designed with optimized profile, the ring die and its driving rim, the feeding scraper, as well as the roller allow for less and uniform wearing losses, better pressing uniformity and good pellet quality. The prolonged service life of wearing parts also results in less down time for replacement and maintenance.

Pellets with good quality bring several benefits: reduced waste, less segregation in the feed, improved palatability and shorter eating periods. It is possible that each pellet mill can produce good quality pellets, but not every piece can produce pellets with good, stable and uniform quality consistently.

In order to achieve clients sustainable benefits, all factors related to the pelleting production performance and pellet feed quality are researched in close cooperation with leading poultry feed and swine feed companies. The study refers to torque of motor, capacity, power consumption, pressing uniformity, pellet uniformity in terms of size, length, density, water stability and fine generation, configuration parameters of die, roller and cutter, as well as the relationships of these factors. What we discovered are used to optimize the V series pellet mills and to provide the best possible processing solutions for feed producers.

Area-to-power ratio of ring die is increased by 15~25% with the optimization of ring die width and liner speed, and feed mash are more evenly distributed for compression thanks to the redesigned feeding scraper, all of which contribute to not only increased output, lower power consumption, but also uniform pellet quality.

Other advantages

In addition to its pelleting and quality stability, the V series is also featured by flowing advantages:

***Safe and reliable production brought by the overload protection device and other safety devices;

***Less and easy maintenance thanks to the free lubrication timing belts, the automatic lubrication system for bearings and the die quick-changing device;

***Optional of different conditioners to ensure the uniformity and hygiene of feed pellets.

Product Link: http://www.machineryshops.com/product/Pelleting-Machine-V4-V6.html

Reviews

Write a review

If you would like to write a review, please login first.