- Overview

- Customer Review

- Purchasing guide

- Service Guarantee

- Specifications

- Download

|

FAMSUN SFSP132 Series Hammermill

|

|

--High Effciency, Low Power, Stable Performance

Water-drop chamber with water-drop shaped second time grinding structure and increased large grinding surface, capacity increases up to 25%.

Dynamically balanced high-precision rotor and top hard wear-resistant hammers, stable running, long service life.

Patented one-step screen holding-down device and fully-open sliding door, easy access and maintenance; CE certified standard design for human & machine safety.

We can offer customized solutions for machine size, feeder, screen, aspiration system and underneath hopper etc.

Real water drop figure grinding chamber design, beyond image and full of connotation.

Interlocked screen of the Water-drop 968 Hammer Mill hold-down fixture (patent) helps to change two-step or multi-step screen pressing into one-step processing, which avoids screen pressing unevenness caused by multi-step working, so that the grinding chamber is guaranteed to run in a fully sealed situation. Patent No. ZL98 2 42415.9

Each rotor is tested and checked in high-precision and dynamic balance in a strict way in order to ensure machine stable running and reduce wearing of bearings and hammer holders, so repairment of equipment is minimized,production efficiency is elevated,and service life of equipment is extended.The machine is equipped with humanized designed sliding opening access door, ease of operation and maintenance,and reduction of labor intensity.Patent No. ZL 98 2 42414.0

The high-precise 14px-diameter rotor is tested by dynamic balancing, enhancing grinding efficiency.

Real water drop figure grinding chamber design, quick discharging.

"W” shaped double grinding structure, output increases by 25%Sliding fully-opening access door,interlocked screen hold-down fixture on the grinding machine, more convenient operation and maintenance.

Step instruction:

1、Click "type" and "power" to choose the type and power of commodity you need.

2、 Click "add to cart"to adding commodity to cart. If the commodity you are purchasing has no accurate price, please click "add to inquiry basket" and fill in your personal information. Our staff will provide quotation for you when verify the orders and automatically help you to complete the purchasing list.

3、You can choose needed logistics way and delivery place when purchasing.

4、 Our staff will provide quotation according to your chosen logistics as verifying the orders. You can click "to pay" to check price and payment. If you have any question about quotation, please contact our staff in time for answers.

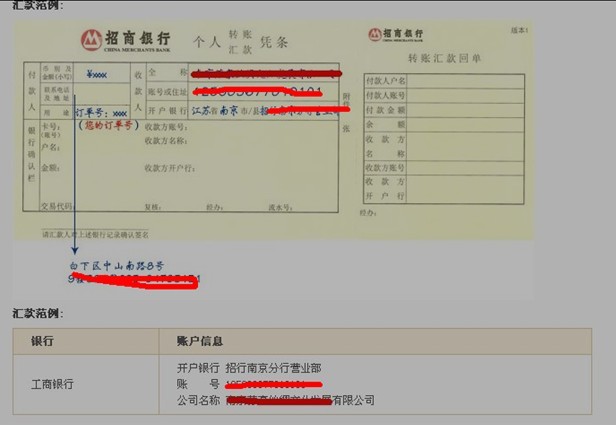

Payment methods:

We support online PAYPAL payment and offline TT payment. Please inform our staff after finishing the payment.

Quality description:

All of our machinery are tested strictly when shipped from factory. And we apply machine one-year warranty.

Contract description:

Generally, we default the online order as the contract. If you need a formal contract, please contact us, we will provide you with the formal contact.

Delivery:

1,Once the advance payment is received,we will arrange production The percentage of advance paymen must be 30% of total amount.

2, Delivery time for single machine is at least 45 days and usually about 2 months. For the complete equipment, we will make proposal, design drawings and confirm with you, thedelivery cycle about 3 months.

3, Total amount must be paid prior to the delivery. TT and online payment are accepted.

4, If you are not satisfied with the offer of logistics, you can appoint logistics company.

5, One-time delivery and partial delivery both are allowed.

6,For machines, sea transportation is recommended; for accessories and parts, air transportation is optional.

7,All price information on website is for reference only, final quotation will be determined by our sales staff according to customers sutitation after inquiries and orders received.

Note:Under special circumstances, the date of delivery will be extended for a reasonable length of time.

Country of origin:

Products are manufactured by Jiangsu Muyang Group Co.,Ltd. of China. Adopting international advanced technology, Muyang imports large proportion of components to do the final assembly.

Acceptance of the goods:

A check on appearance should be made immediately when the equipment is transported to the destination. If it is sure there is any damage caused during transport, a necessary claim procedure must be taken according to the supply contract. The repair expense shall be borne by relevant risk undertaker.

Maintenance and cleaning

Only professional persons can carry out maintenance and shall well know relevant stipulations in the documents provided by us. These stipulations are helpful for keeping the equipment in good condition, reducing wear and prolonging the service life. Cleaning shall be done according to relevant legal stipulations and explanations in the documents provided by us.

Storage

The equipment, which cannot be installed in predetermined place immediately, must be stored in a weatherproof place with facilities against external infringement in original packages. Any loss arising from storage shall be only conducted as per the principle specified in the Supply Contract.

Installation

The equipment and parts manufactured by Jiangsu Muyang Group shall be installed only by the trained technical personnel based on installation specifications provided together with the equipment.

Startup and commissioning

Startup and commissioning shall only be done by trained personnel. The instructions and operation regulations in provided documents before startup. Lubricating before startup, such as oil for variable speed devices.

Accident prevention

The accident prevention rules in related documents must be well known and MUYANG Group devotes to manufacturing machinery equipment according to Standards (CE Certification Standards).

Customers shall tell us the local manufacturing. Additional expenses there from shall be borne by customers.

Contact us

If you have any questions or after-sale problems, please contact us in time.

TEL:+86-02134970680(00:00--10:00 GMT)

E-Mail:

|

MODEL |

SFSP132×36 |

SFSP132×65 |

SFSP132×102 |

|

POWER(KW) |

75/90/110 |

132/160/200 |

250/315 |

Description:Thank you for visiting machineryshops.com, where you will find thousands of products offered at incredible prices.