- Overview

- Customer Review

PTCL Vertical Coater

design for low oil amount spraying(spraying amount 1%~6%)

Normally, the drum coater is always one and only choice for low oil amount spraying for pellets. The spraying uniformity of drum coater is acceptable, but the low spraying accuracy leads to serious waste of oil; furthermore, the high residue rate and heavy oil contamination are also defects of drum coater.

Customers need advanced solutions for low oil amount spraying urgently.

FAMSUN Europe R&D department designed the excellent PTZL series vacuum coater based on the concept of vertical mixer for high oil amount spraying.Through updating the PTZL series vacuum coater and removing the vacuum pump, FAMSUN designed PTCL vertical coater for extruded pellets, which reduces the cost of investment and use for customers.

Advanced Structure Design

Adopt PTZL coater structure, designed by FAMSUN Europe R&D department

Performance Features

advantages of PTCL coater, compared with drum coater

high control accuracy

• batch-wise coater, self-weighing, no batching scale, high accuracy gate, pellet weighing accuracy ≤1%

• double-tank liquid scale, liquid weighing accuracy≤0.5%

Closed-type coater, no oil contamination

• reducing oil waste, saving cost

• improving production environment

excellent spraying uniformity, low residue rate

• CV≤ 7.0%,residue rate≤ 0.5 ‰

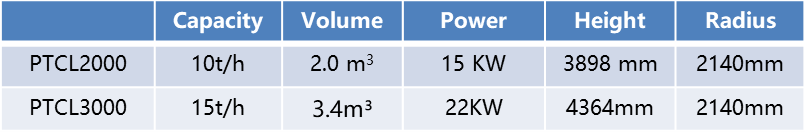

Process configuration & parameters

0 OUT OF 5

(0 Review)