Home>>News

Machineryshops.com

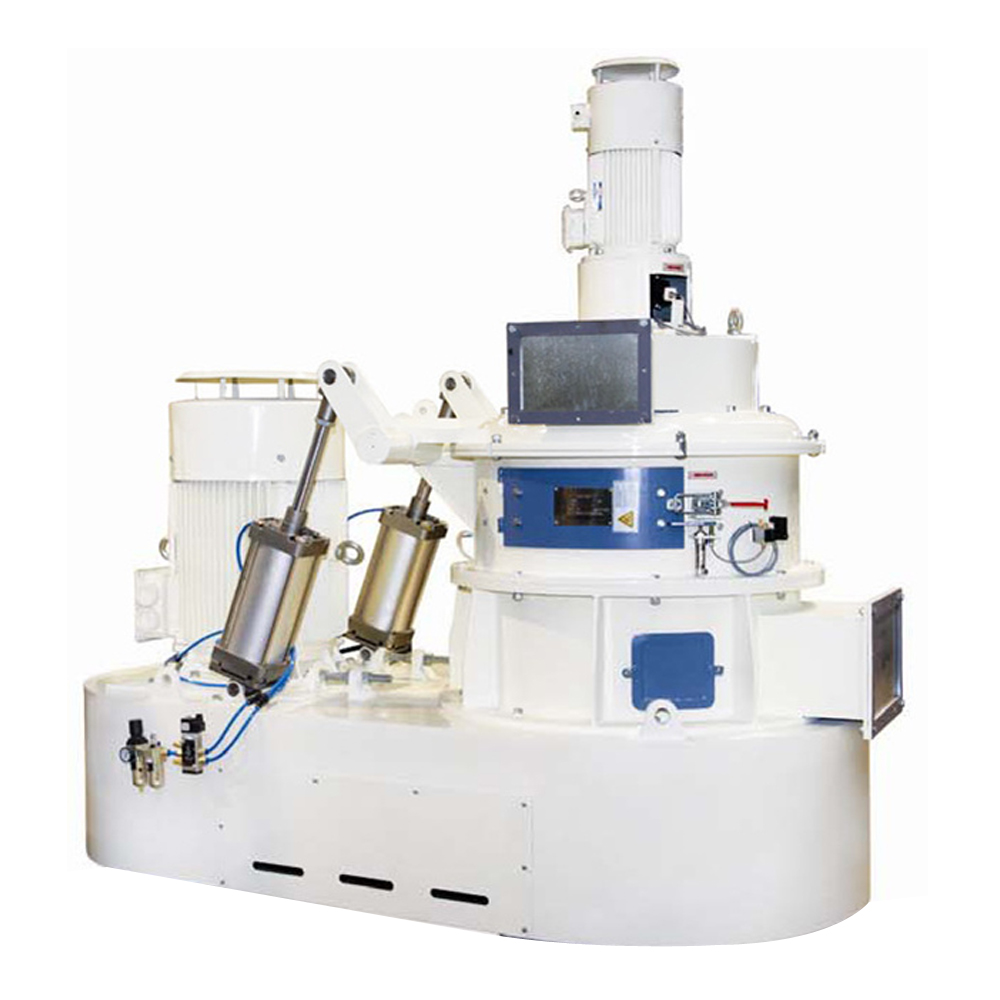

The Sixth Generation of Muyang Grinding Equipment

The sixth generation of Muyang no-sieve, ultra-fine grinding equipment is specialized for secondary grinding of auqafeed extrusion. More than two years’ production practices in aquafeed mills in China have demonstrated that the advanced model is able to grind ingredients into finer particles with higher output and lower power consumption, by comparing to fine-grinding hammer mill and its previous generation SWFL130E Pulverizer.Pulverizer vs. Fine-grinding hammer mill

When using a fine-grinding grinding machine as the secondary grinding machine for the high-fiber, high-protein and oil-rich fish formula, severe production loss may occur due to fire risk, short service life of screen, more down-time for screen-changing or maintenance, and non-uniform product quality. A screen of 0.6mm aperture is liable to be blocked or broken. Actual productions proved that 2-6 screens or more of that may have broken in a day's aquafeed extrusion production with a fine-grinding hammer mill.

SWFL130F vs. SWFL130E

1) Smooth grind, because of the streamlining grinding chamber designed and aspiration system for conveying;

2) Good product quality thanks to low temperature processing and without nutrition degradation;

3) No sieve furnished to avoid over-grinding, less maintenance;

4) Good particle size reduction performance.

However, the 130F is more distinguished in production capacity, energy efficiency and service life of wear parts.

Reviews

Write a review

If you would like to write a review, please login first.