Home>>News

Machineryshops.com

Muyang Feed Mill Engineering

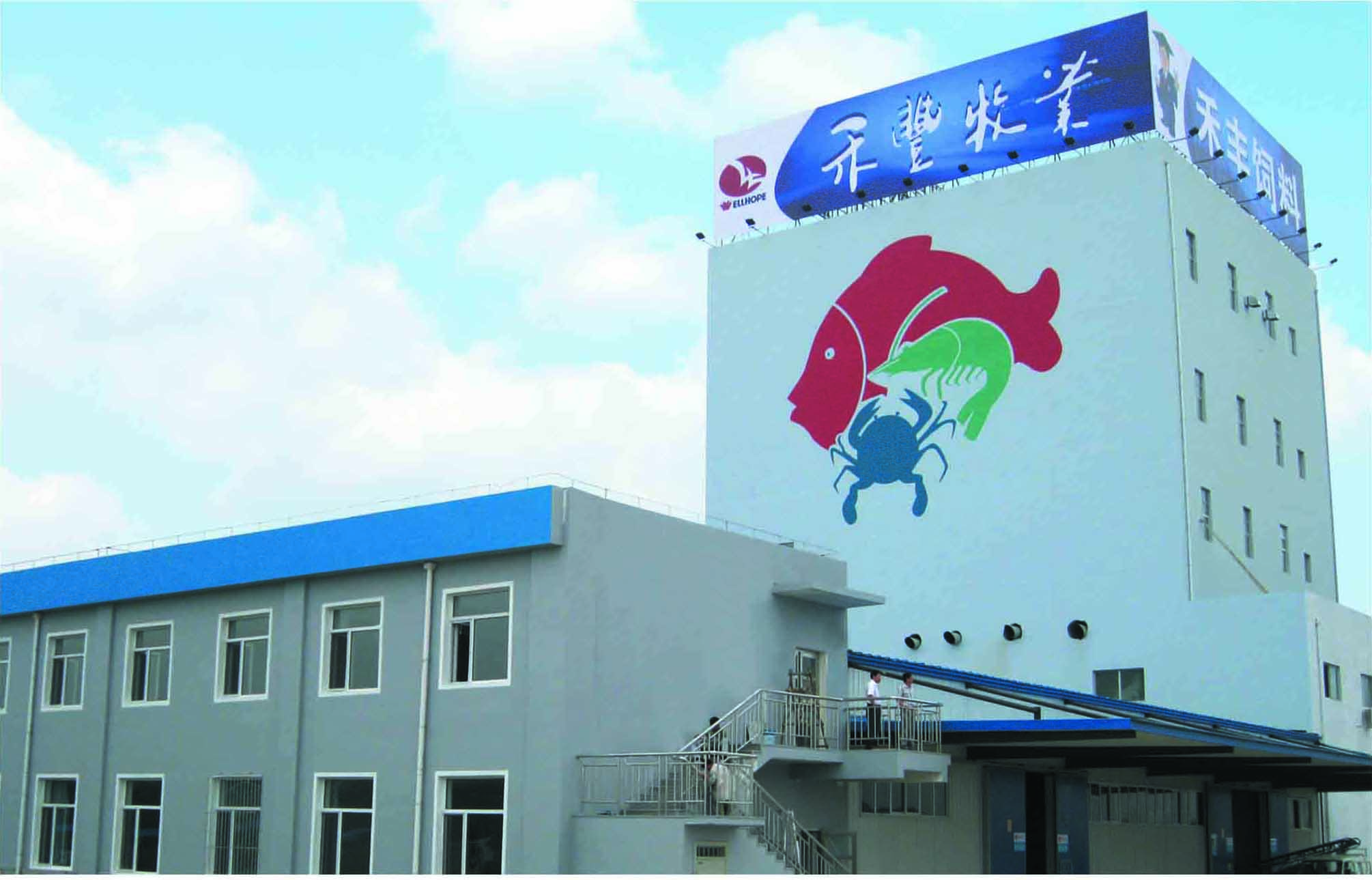

In the early nineties, Muyang already entered the field of feed complete engineering, the company now has more than 120 professional and technical personnel in the field of mechanical design and manufacturing, heat treatment, feed processing, civil engineering, electrical automation, computer application, animal nutrition, ventilation and marketing. Meanwhile, Muyang provides customers with one-stop service from design, manufacturing to installation and commissioning. In China, Southeast Asia, the Middle East, North America, Australia and many other countries and regions, Muyang has constructed nearly 2,000 various types of turnkey projects, including animal feed project, aquatic feed general engineering, pet feed engineering, forage engineering, premixed feed engineering, concentrated feed engineering, bio-feed enzyme protein engineering, hops particle production line, which has won wide recognition from customers at home and abroad.

1.Feed production solution design

(1)Determine the scale of feed mill

(2)Determine the feed process and recommend equipments

(3)Control mode selection

(4)Plant structure selection

(5)Planning the general drawing of plant site

Muyang leading aquatic animals (fish, shrimp, crab, etc.) feed production line solutions meet customer's individual line from 0.5 to 30 tons per hour production needs. Based on the ruminant feed market characteristics, Muyang also provides a full range of ruminants (cattle, sheep, etc.) animal feed production solutions and turnkey projects, Muyang ruminant feed production line solutions meet customers 5 to 45 tons per hour production needs.The premix feed production line solutions meet customers 1 to 45 tons per hour production needs with turnkey service. Pet food production line solutions meet customers' individual lines from 0.1 to 15 tons per hour production needs, providing turnkey engineering services.

Reviews

Write a review

If you would like to write a review, please login first.