Home>>News

Machineryshops.com

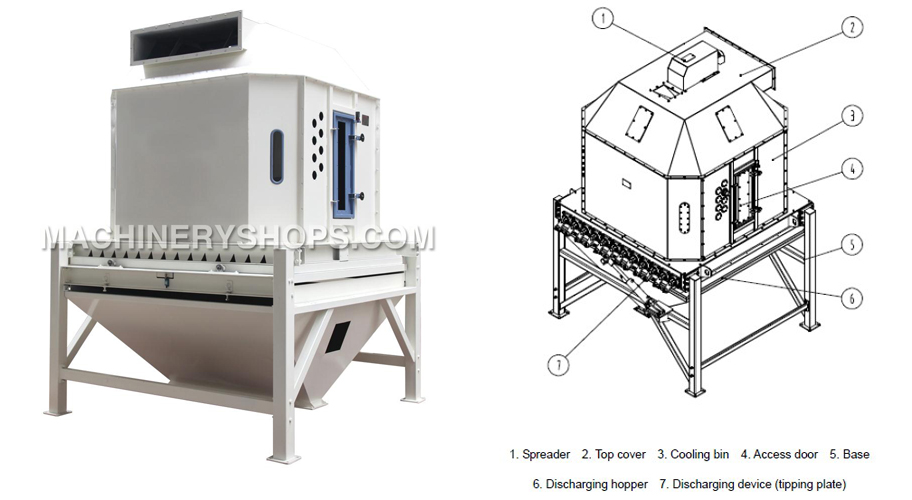

MUYANG SKLN Series Counter Flow Cooler

SLNFA Series Tipping Plate type Counter-flow Cooler is used widely for cooling process in feed industry. It is applicable for cooling all kinds of pellet feeds such as pelletized feeds, expanded feeds, flakes and other granular feeds, especially applicable for cooling expanded pellets.The cooler mainly consists of a base, a top cover, a spreader, a cooling bin, a discharging device and a hopper. The wet and hot material goes into the cooling bin through a closed feeder or air lock and is spread evenly on multiple parallel tipping plates by the spreader. When the material is piled to a certain height, the level indicator above the hopper induces the level information and sends out a signal, so that the hydraulic cylinder pushes the crank link mechanism to move. The tipping plates revolve round their shafts respectively. Then the material falls from the gap between the tipping plates and flows evenly into the discharging bin. When the tipping plates move to a certain angle, the tipping plate opening indicating bar touches the travel switch, and the hydraulic system makes the hydraulic cylinder piston move to the opposite direction by the action of hydraulic reversing valve, then tipping plates stop in the preset position.

If the height of the material is still higher than that the level indicator positioned, the tipping plates will repeat the above discharging process. Or else, it will stop in the closed position waiting for the next discharging cycle. In the foregoing process, the cooling fan is open all the time.

The cooling air flows from bottom to top and changes from cold to hot. The material goes down gradually and changes from hot to cold (countercurrent cooling principle). The hot material in the upper part of the cooling bin comes across hot air and the cold material in the lower part comes across cold air, thus the cooling efficiency becomes higher and the material gets uniform and sufficient cooling. So the quality of product is guaranteed.

It is characterized by vertical layout, concise and beautiful appearance with advanced counter-flow cooling principle, swinging tipping discharging mechanism controlled by a flexible hydraulic driving system, smooth discharging process, adjustable discharging flow rate and speed, and uniform discharging amount.

The cooling bin with an octagonal section can avoid dead angles of cooling and this is favorable for material cooling, and the new rotary spreader ensures that materials can be evenly and thoroughly cooled, and can decrease the breaking ratio obviously.

The temperature of material after cooling is not +3~5℃ higher than room temperature, the dehydration rate is in the scope of 1%~3.0%, so the storage time of high-quality pellets is prolonged. The equipment is complemented with access door on the front face for convenience of daily maintenance and repair. The side face and top cover are equipped with observation windows for the convenience to observe running status of the equipment.

Except for this type cooler, Muyang also provides you with GKLW Series Horizontal Drum Cooler, SWLN Series Pellet Combined Stabilizing Cooler and SWDB Series Swing Type Pellet Stabilizer.

Reviews

Write a review

If you would like to write a review, please login first.