|

|

|

|

Silo Storage engineering

Over 40 years experience and rich expertise;Wide storing capacity range, 1~18000 tons;Product kinds (assembly silo or Lipps silo) to be selected at one’s pleasure;

Effective global sales network with reliable support service.

|

|

|

Muyang Storage Engineering Co., Ltd, the exclusive holding enterprise under Jiangsu Muyang Group, is specialized in the research, design, installation and after-sales service of material storage technologies. The corporation has various kinds of silo models and specifications, such as bolt assembly type steel silo, spiral type steel silo and insulation silo, for fulfilling the different needs of our clients. Either by single silo capacity or total silo quantity built, we are the largest comprehensive facilitator in Asia.

|

|

Engineering Introduction:

|

|

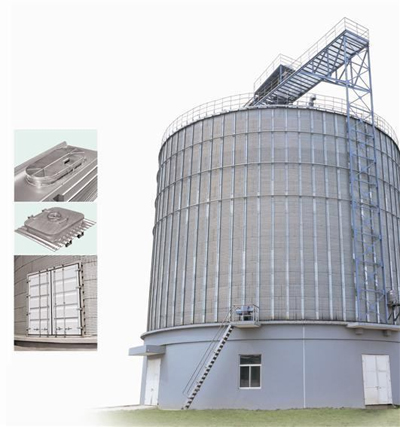

Bolt assembly silo

Bolt assembly type steel silo technology is the most advanced among the silo- building technologies in the modern world. Widely used in the American and European countries, bolt assembly type steel silo takes the largest market share in silo area. The modularized production avoids any human factor damages and increases accuracy, preventing damages to the zinc layer during installation. The sidewall and stiffeners are connected by detachable high strength bolts.

|

|

|

Advantage

1. Large capactiy

Silo roof angle 35 degree, more storing space.Single silo capacity is up to 17000 tons, with comprehensive configurations to meet different customer’s requirements.

2. High accuracy

Complete advanced processing equipment and technology are introduced from USA to effectively ensure working accuracy and reduce damage to galvanized layer.

3. Less residues

External installable stiffeners contribute to less grain residues on silo walls.

4. Detachable and movable

With standardized and modularized production, components and parts have a high standardization and good interchangeability, thus can be partially replaced or completely transferred.

|

|

|

|

|

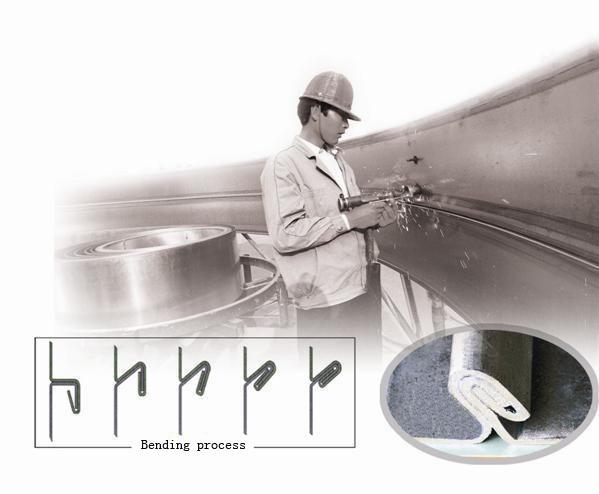

Spiral type steel silo

|

|

|

Advantage

1. Good sealing performance

With five layer spiral crimping, the seams are very tight, and the silo is of a good sealing performance and can be used as a fumigating silo.It is also suitable for storing building material such as cement.With seal glue embedded into spiral crimping seams, the spiral silo can store fluid material such as waste water.

2. Small area occupancy

Height and diameter are optional in a wide range. The distance between two silos can be minimized to 500 mm to make the most of available space and residue area occupancy.

3. Long service life

Best sheets match to silo body enables a normal service life up to 20-25 years.

4. Short construction period

Highly mechanized construction of spiral a silos on site, short construction period.

|

|

|

Insulation silo

|

|

|

Advantage

1. Thermal insulation

Grain temperature change gradient inside silos is lower than that outside, thus not likely to have condensation of moisture.

2. Safe grain storage

Storing in a low temperature, increases the grain storage stability, keeps the grain quality and prolongs the safe- storage period.

3. Low fabrication cost

With installing an insulation layer (polyurethane froth, rubber sponge, glass fiber ect.) on the outer wall, insulation silo can have a low fabrication cost compared to concrete silo.

|

Case demonstration:

|

|