- Overview

- Customer Review

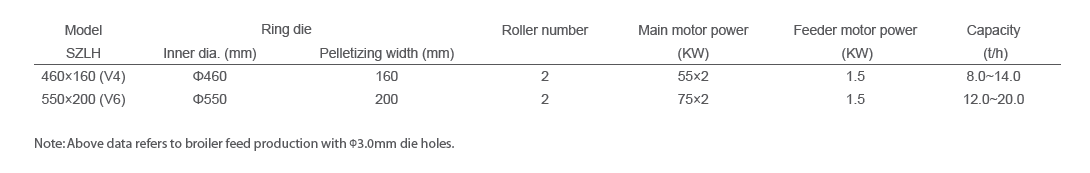

- Specifications

- Distinguished pelleting stability

Unique double-timing belt driving and cooling system for motors output same torque simultaneously, sectional ring die clamper for fixing ring die onto rotor firmly, widened supporting area of main shaft as well as wearing reduction designed working parts, are all enabling long-time stable production.

- Superior pellet quality

Conditioning system (optional) DDC Conditioner and/or STZW Hygienizer for longer retention time and more beneficial to gelatinization and sterilization of feed, contributing to consistent top quality products. Pellet size ranging from Φ2.0mm toΦ10.0mm.

- High output

Optimized feed-to-pellet deflector structure, widened ring die working area (+15~25%) to enable consistent high output and low energy consumption.

- User-friendly

Hydraulic system for die change and roller adjustment, quick and precise operation; auto-lubrication system and die & roller lifting device, saved labor; overload protection and door protection for human and machine safety.

- Customized solution

Optional of different conditioners and different ring die mounting patterns to meet different production demands.